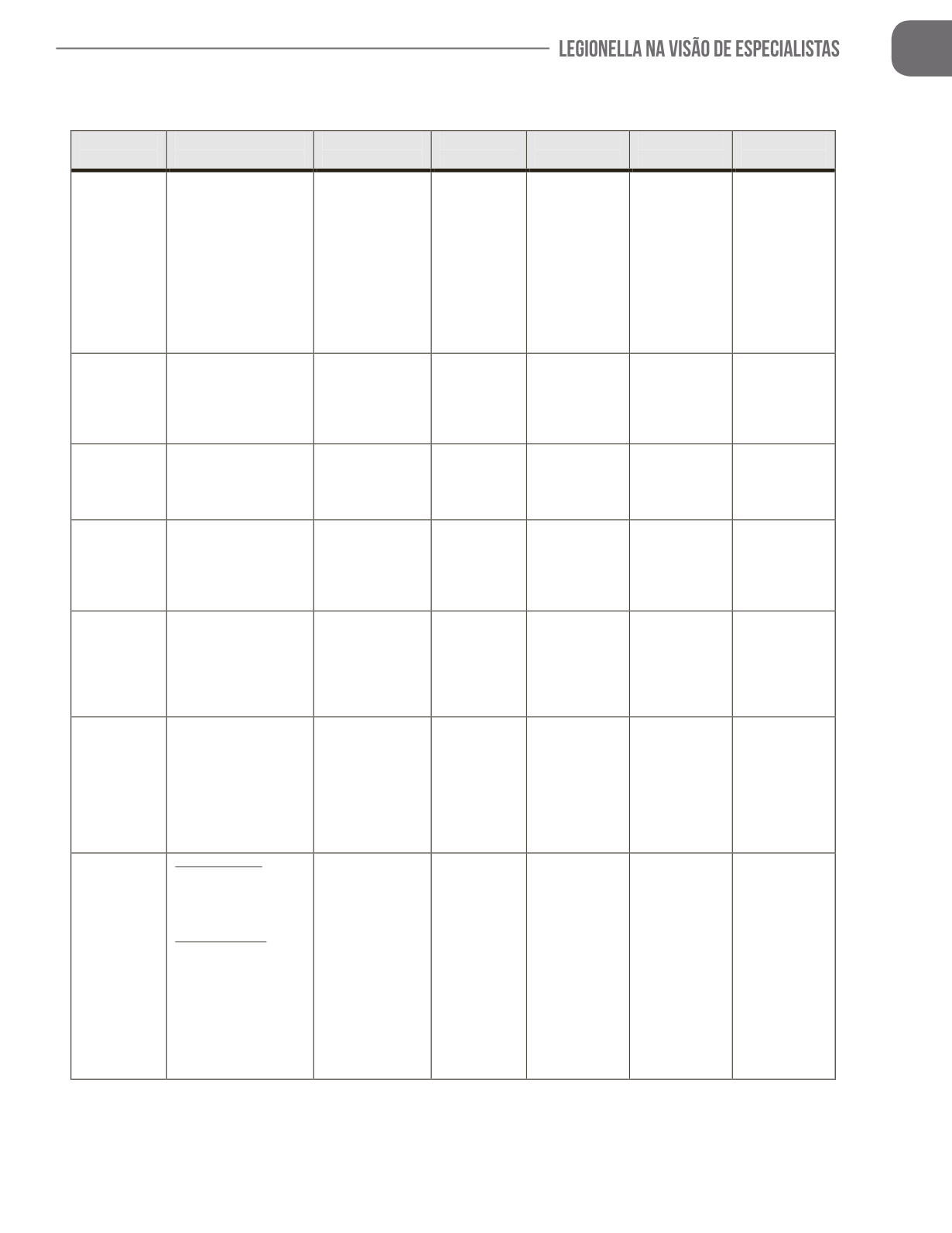

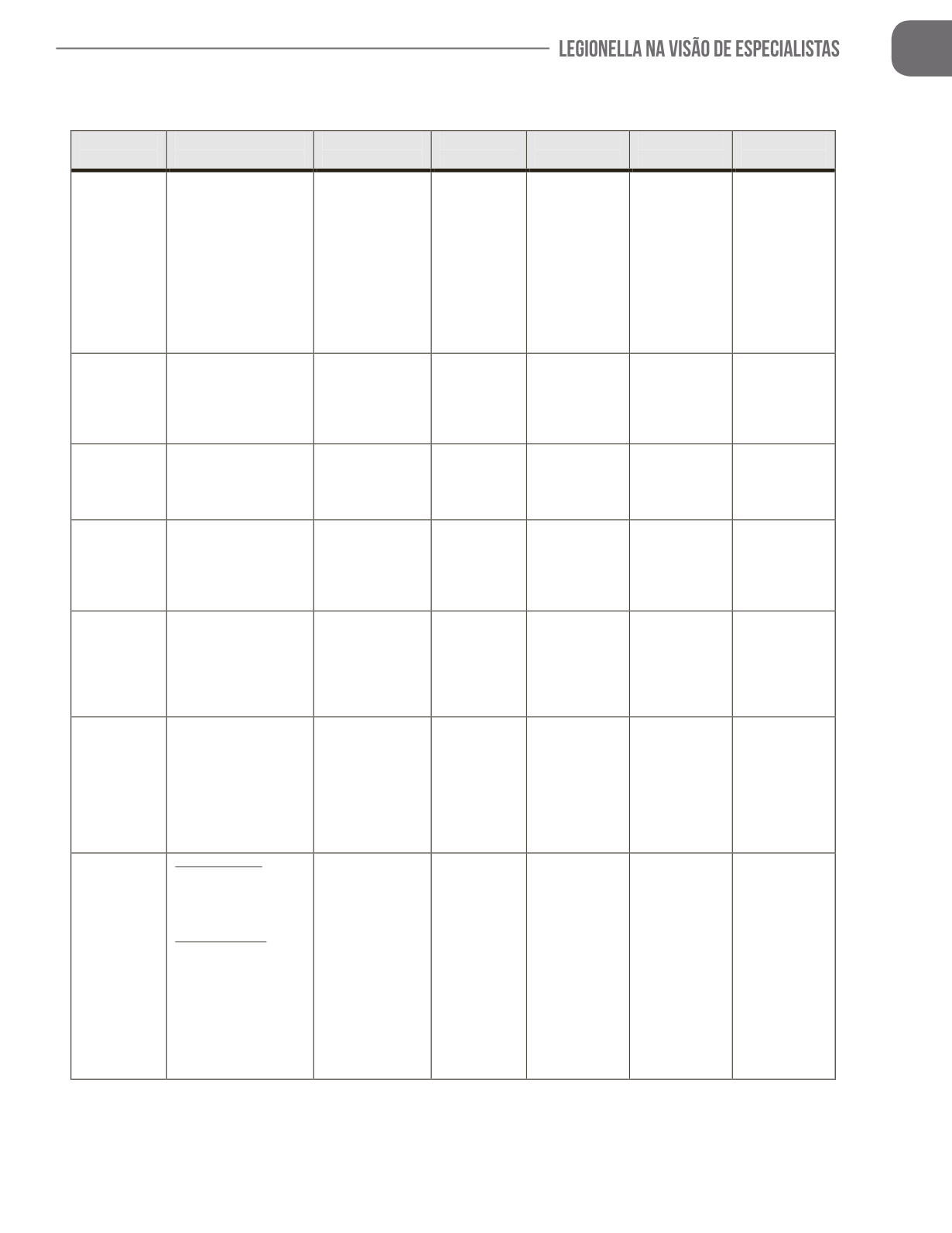

129

Processing

Step CCP

Critical Limit for

Hazard Control

Monitoring

Method

Monitoring

Frequency

Corrective

Actions

Verification

Records

Verification

Procedure

Cold water

distribution

–

sinks/

showers/

sprayers

0.2-1.0 ppm free

residual chlorine,

continuously

Flushing protocol

specification

Flushing execution

specification

Samples from

distal sites for

DPD chlorine test

Online hazard

control monitoring

logs

1x per week

As performed

Facilities

Operations:

Flush the

system and test

the time

required to pull

measurable

chlorine to the

outlet. Add 3

minutes to

initial flush

time

Weekly log

sheets

Online data

management

system

Facilities

Operations

Supervisor

verifies each

week

Cold water

distribution

–

drinking

fountains

Maintenance per O/M

manual, PM procedures

and filters (when filters

are used)

Follow O/M

manual

instructions for

each respective

drinking fountain

model

Per

manufacturer

Water

Management

Team reviews

situation

Operations

work logs

Facilities

Operations

Supervisor

verifies each

quarter

Cold water

distribution

–

ice machines

Maintenance per

manufacturers’ O/M

manual

Follow O/M

manual

instructions

Every 6

months

Water

Management

Team reviews

situation

HVAC group

work logs

Facilities

Operations

Supervisor

verifies each

quarter

Emergency

eyewash and

showers

–

cold or hot

0.2-1.0 ppm free

residual chlorine,

continuously

Flushing 1x/wk for

3min

Samples for DPD

test

Online hazard

control monitoring

logs

Emergency

Showers -1x

per month

Eyewash -1x

per week

If no

measurable

chlorine, flush

for 7 min or

until water is

clear

Operations

work logs

Facilities

Operations

Supervisor

verifies each

month

Heating

120-125

°

F at each

building at hot water

heaters

105-120

°

F at distal

sites for scald control

Visual

thermometers at

hot water heaters

or automated

monitoring

3x per week

for visual

thermometers

at hot water

heaters or

continuous for

automated

If temperature

is low,

Maintenance is

dispatched to

investigate/repa

ir

Manual logs

or data logger

used for power

plant

Facilities

Operations

Supervisor

verifies each

week

Hot water

distribution

0.2-1.0 ppm free

residual chlorine,

continuously

Flushing protocol

specification

Flushing execution

specification

Samples for DPD

and temperature

measurements at

pre-defined

sample locations.

Online hazard

control monitoring

logs

1x per week

Water

Management

Team reviews

data regularly

Weekly log

sheets and

online data

management

system

Facilities

Operations

Supervisor

verifies each

week

Decorative

fountain

treatment

Inside Locations: 1.0-

2.0 ppm free residual

chlorine, continuously;

pH 7.2-7.8, cyanuric

acid (if used) <20ppm

Outside locations:1.0-

3.0 ppm free residual

chlorine, continuously

pH 7.2-7.8, cyanuric

acid 30-50ppm

Clean filters, check for

cracks and leaks, clean

and vacuum each week

DPD chlorine, pH

and cyanuric acid

(if necessary) for

grab samples 2

nd

floor pediatric

unit; 7

th

floor

meditation room

garden fountains.

Online hazard

control monitoring

logs

3x per week

1x per week

If chlorine

levels are low,

add more

product and

retest.

If solid product

level is low in

dispenser, add

more product

and retest.

If cyanuric acid

is too high,

drain half the

volume, refill

and retest

Weekly log

sheets; test

results logged

and stored in

Facilites

Operations;

MMS work

orders and

online data

management

Facilities

Operations

Supervisor

verifies each

week

Table 7